Kroger expands online fulfilment automation with Ocado

Kroger has ordered further large-scale automation solutions for online fulfilment from the British technology company Ocado. As the second-largest US retailer announced this week, proprietary Ocado technologies such as On-Grid Robotic Pick and Automated Frameload are to be implemented in all eight existing Customer Fulfillment Centers (CFC). Ocado’s technology will also be used in already planned future CFCs. With this step, Kroger aims to further reduce the cost of deliveries from its e-commerce warehouses and improve its customer service.

The timing of the announcement is noteworthy, as Kroger had revealed in September 2023 that the introduction of automated fulfilment centres with Ocado was under review. The two companies had previously reached an agreement in 2018 to rapidly bring the UK company’s automated fulfilment solutions to the US to give Kroger a competitive advantage in the growing e-commerce market.

Rodney McMullen, chairman and CEO of Kroger, told the retailer’s investors in September last year that, in a departure from its original growth plans, the development of new e-commerce locations with Ocado was on hold: “Until we’re sure we have a clear path for the existing locations.” The news came at a time when retailers were struggling with fluctuating e-commerce sales after rapid growth in the first few years of government hygiene measures.

Strategic investment in new technology

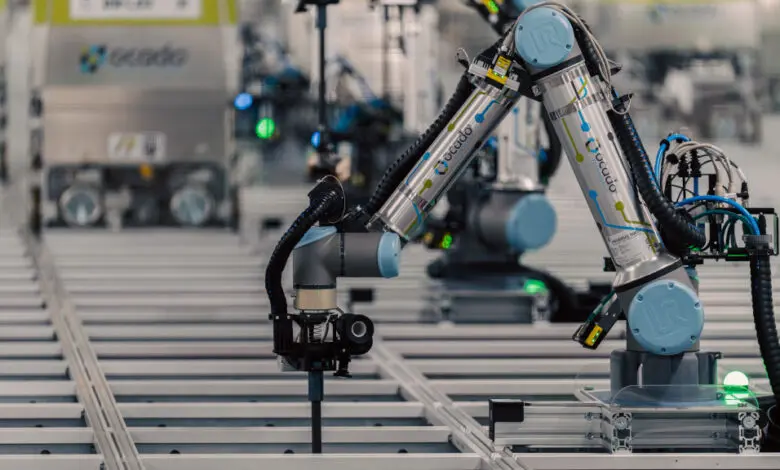

Now it seems that Kroger has overcome the period of uncertainty regarding its e-commerce locations. The retailer’s decision to invest in new technology reinforces the ongoing relationship between Kroger and Ocado. One of the online fulfilment solutions ordered by Kroger is the UK company’s on-grid robotic arm, which is installed directly on a system of individual totes. Bots working directly on the totes automatically transport the individual products required for a customer order into the vicinity of the robot arm.

The robotic solution from Ocado sucks goods required for an order and stows them close together in customer bags at high speed and with precision. Thanks to the suction mechanism and with the help of sensors and image processing, Ocado’s robot is able to process tens of thousands of individual items of extremely different sizes, shapes and textures. As the installations of Ocado technology at other retail companies show, the robotic arm can pick over 70 per cent of an extensive range of food products.

Computer vision supports smart packing

Ocado’s Automated Frameload reduces physically demanding work for warehouse staff. The containers packed by the robot arm with all the ordered goods are automatically placed in stable transport boxes and prepared for delivery. Ocado’s solution works without human intervention. Computer vision determines the dimensions and shape of the unit for the customer and enables efficient alignment in the transport crate. Any necessary adjustments to the direction are automatically handled by the warehouse system and carried out in real time.