Codè Crai Ovest has started to deploy an app called `Last minute sotto casa' by start-up LMSC to minimise food waste. The Italian cooperative uses it to inform shoppers on items to be bought at lower prices shortly before they reach their expiry date.

Read more >>Prudsys

Every year, almost 500,000 tonnes of food waste are caused in the retail sector in Germany alone, according to the UN Food Waste Index Report from last year. This is not only bad for the industry's image – the commercial damage caused by food being written off without sale is also immense. The problem has been recognised in retail companies,…

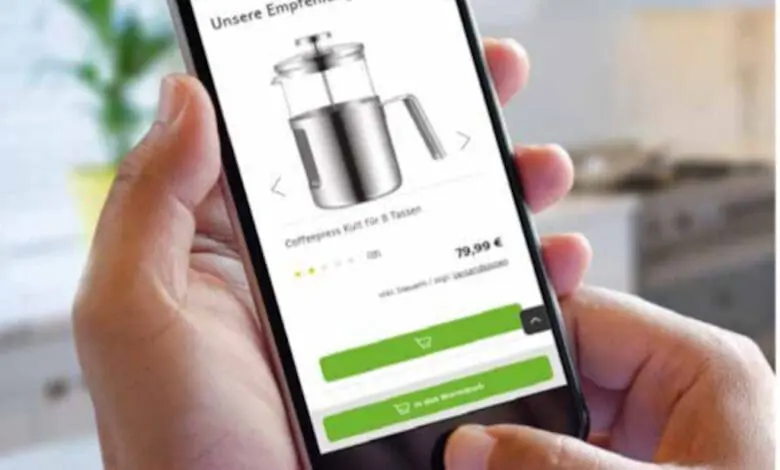

Read more >>Online shopping club Brands4friends has automated pricing for its entire product range with AIR Dynamic Pricing from Prudsys. The AI-based solution from the GK Software Group company has improved the retailer's margin by three percentage points.

Read more >>WMF personalised its customer approach in newsletters and online shop with AI solutions from Prudsys. This boosted the click-through rate and significantly increased sales from recommendations.

Read more >>