Arvato automates Douglas’ omnichannel distribution centre with Knapp

Together with service provider Arvato, Douglas has put a complex automation solution from Knapp into operation at its new central warehouse in Hamm. The system comprises a variety of connected technologies aimed to largely automate order processing for the retailer’s stores and online business. Its high-quality beauty products need to be handled with particular care.

The cosmetics retailer opened its omnichannel logistics centre in Hamm in September 2023 to consolidate its six previously decentralised warehouses into one location. At the 38,000 square metre site, Arvato took over the entire logistics operation for store deliveries and online orders, including returns management, in the DACH region.

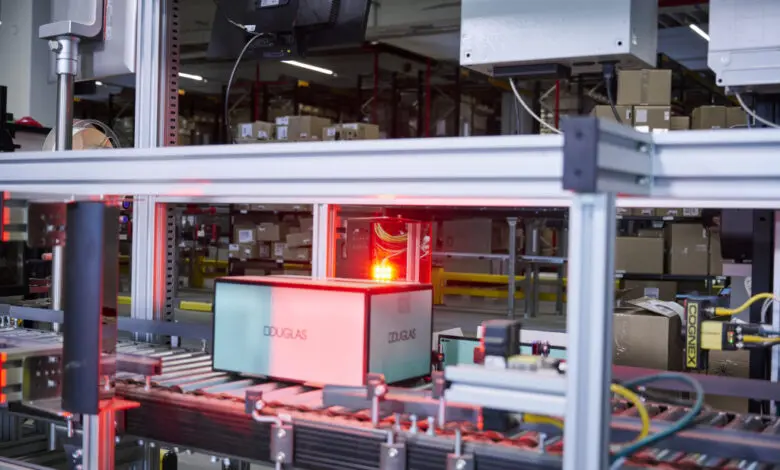

The automation solution is now fully operational after an implementation phase of 25 months. Centrepiece of the solution is a Knapp 2D shuttle system, which, according to the technology provider, is the largest of its kind in the cosmetics sector worldwide. It is part of an overall system consisting of three cross-belt sorters, devices for automatic master data recording, pick-by-light picking stations for samples and large-volume items and automatic carton sealing machines.

System files master data automatically

Following Goods receiving, packages are either stored or transported to decanting stations. There, the system automatically records important master data and sends it to the warehouse management system. The solution suggests a suitable container configuration to the employees at the stations and provides these from a buffer or the shuttle system.

Knapp’s Evo Shuttle 2D has more than 130,000 storage spaces and can store and retrieve 12,500 containers per hour. In total of 550 shuttles carry out their work on 25 levels and 22 aisles. The small parts warehouse holds the large majority of the retailer’s 70,000 SKUs. A lift system transports the containers, which are stored double-deep, to the goods-to-person workstations for picking.

Manual picking using Pick-to-Light

Employees pick customer orders at a total of 32 picking stations of the Pick-it-Easy Evo series. Here, they have simultaneous access to two source containers and four dispatch cartons. Depending on order size, the required carton is automatically erected and fed to the employee via a cross-belt sorter. Once the order has been picked, cartons are sent to the area for fast-movers and product samples. Here, pick-to-light systems support the employees assembling the orders.

If customers have also ordered large-format products, employees add these to the packages at separate manual picking stations. The B2C orders then arrive at one of eight pick-to-light stations, where a grid carton is added to the parcel to secure it for transport. An outgoing goods sorter then feeds the deliveries to automatic carton sealers and labelling machines.

Software controls the processes

The interaction between manual and automated areas is controlled by warehouse logistics software KiSoft One from Knapp. It ensures error-free processes and uniform capacity utilisation throughout the entire logistics operation. It also analyses all relevant system data. It can thus help to derive trends and forecasts.